At Hooker Engineering Australia we can provide a full range of workshop services leveraging off our manufacturing background. Similar to our system builds all of our workshop services are supported by the appropriate engineering oversight. We consider this engineering guidance an important point of differentiation in this space and this helps to deliver the best outcomes for our customers.

Refurbishment

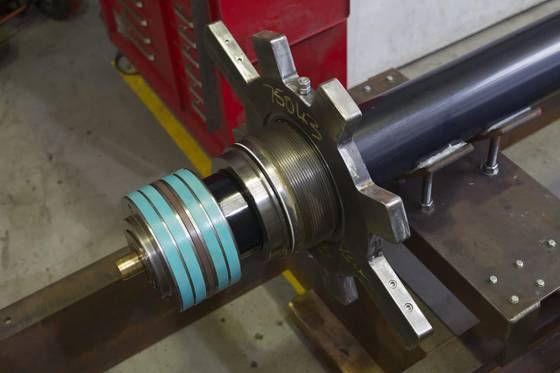

We can provide refurbishment of mechanical and hydraulic equipment with the appropriate level of technical engineering supervision. This level of engineering guidance is critical to ensure the optimum outcomes are achieved via root cause analysis and detailed engineering review at the front end. Our intent is always to remedy the root cause which offers the best outcome for our customers rather than a same for same refurbishment approach.

Leveraging off our manufacturing capabilities, our fabricators can complete structural remediation and upgrades as required. All mechanical and electrical assembly and refurbishment are also completed in-house as well as rigorous function testing prior to release to our customers.

Testing

Our meticulous testing process ensures all our equipment and workmanship meets the required quality targets. We have a dedicated testing area with a permanent capacity of 110 kW and pumps with a range of flow and pressure capabilities. With the appropriate planning, we have been able to test larger systems, including a 250kW/1000kNm mill inching drive.

We can also pressure test and cycle (air bleed) luff cylinders prior to installation into machines during construction or shutdown work. A dedicated luff cylinder frame is available for stroking of large luff cylinders.

Assembly

In many cases, the hydraulic system is designed to be part of a larger drive or assembly. We can provide workshop resources to assist with pre-assembly of the overall unit to permit for a full system function testing. Where required, we can also include a customer demonstration.